The Shop is where everything is created. The Foundry, Finishing Shop, Iron Shop, Lighting Department, Lock Department, Machine Shop, Special Work Shop and Tin Shop all play key roles in the making of our products.

Foundry

In our foundry we do sand castings. We pour brass, bronze and gray iron. Adrian and his assistant are pouring melted brass into a sand mold.

The crucible in the foundry is filled with molten brass which the guys pour into the sand molds.

Finishing Shop

The finishing shop is where we do much of the final work on our brass products. Sanding, final shaping, polishing and finishing processes are all done here.

Brothers Miguel and Raphael do the buffing and antiquing for our brass items.

Iron Shop

Garrett Ball, our blacksmith, is shown here forging hinges.

Here Ellen Durkin is forging rattail bolts.

Lighting Department

Joe Kelly, one of our lighting specialists, is working on a chandelier. The parts are made in our foundry.

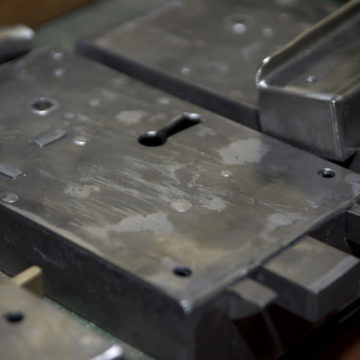

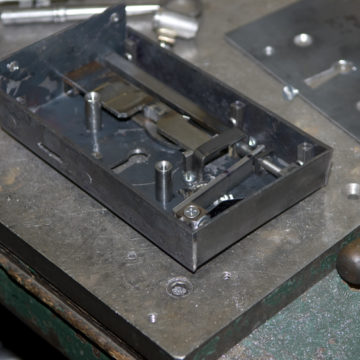

Lock Department

This is our locksmith Tom Peters building a rim lock.

More shots from the Lock Department.

Machine Shop

Dave Gray and Jim Hall working on lathe and screw machines.

Special Work Department

The function of the special work department is to provide services that are outside of our regular production process. This is where we build iron chandeliers and other custom lights, restore and refinish original hardware and do custom copies of original hardware.

Bob Ball runs our Special Work department. See our Custom Work page for details.

Spencer Barnes is making pattern work for custom jobs.

Tin Shop

Alysa Brown, our tinsmith and metal finisher, is fabricating a copper lantern.